A bunch of disparate parts. Some from eBay, a few were left over from old projects, like from High School times.

I wanted the faceplate to be tidy, things nicely lined up, etc. so I did all the drilling on the milling machine.

Plans are good!

And look, the big 4" hole missed that screw!

Dusty work.

Faceplate, populated.

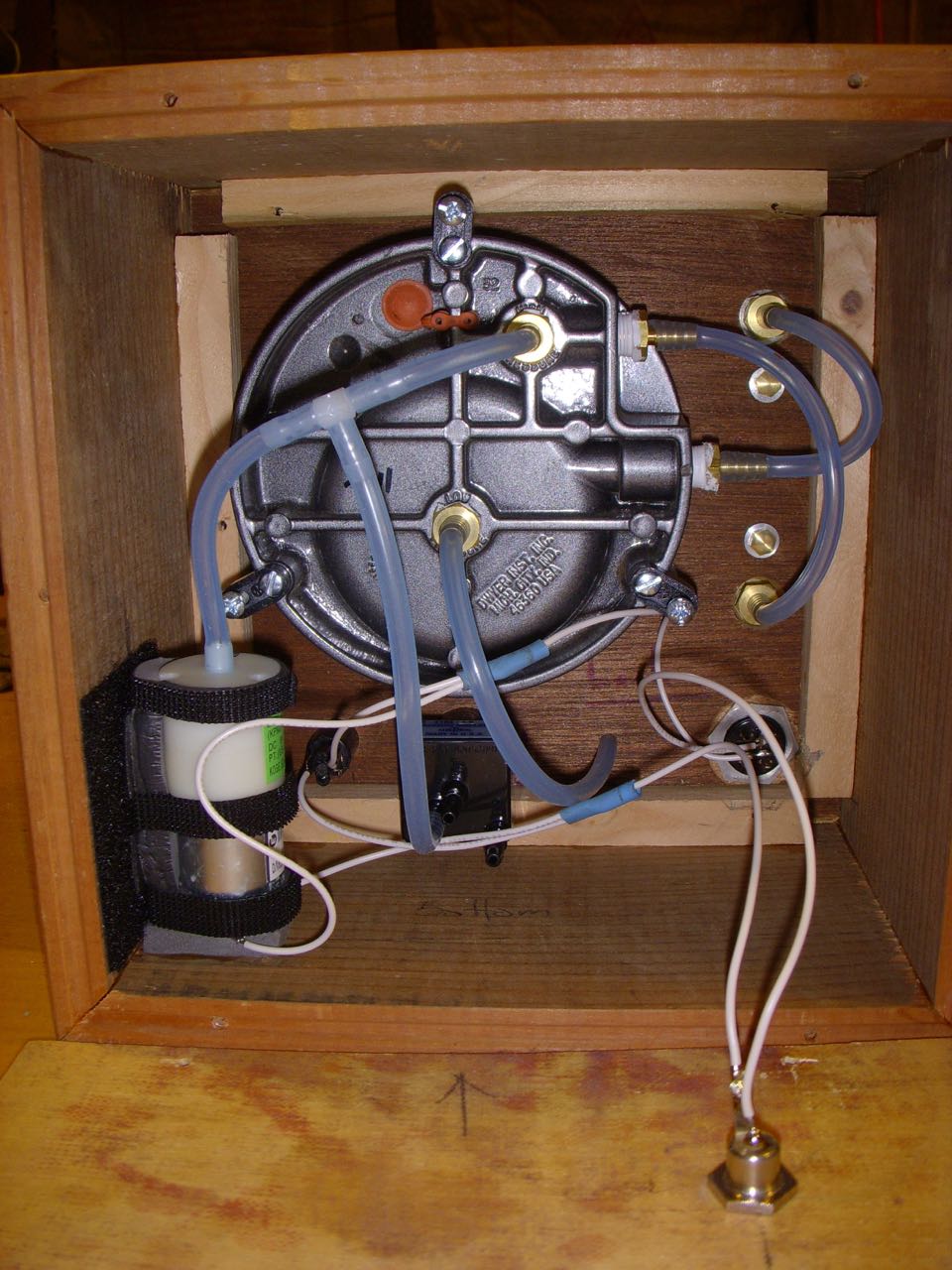

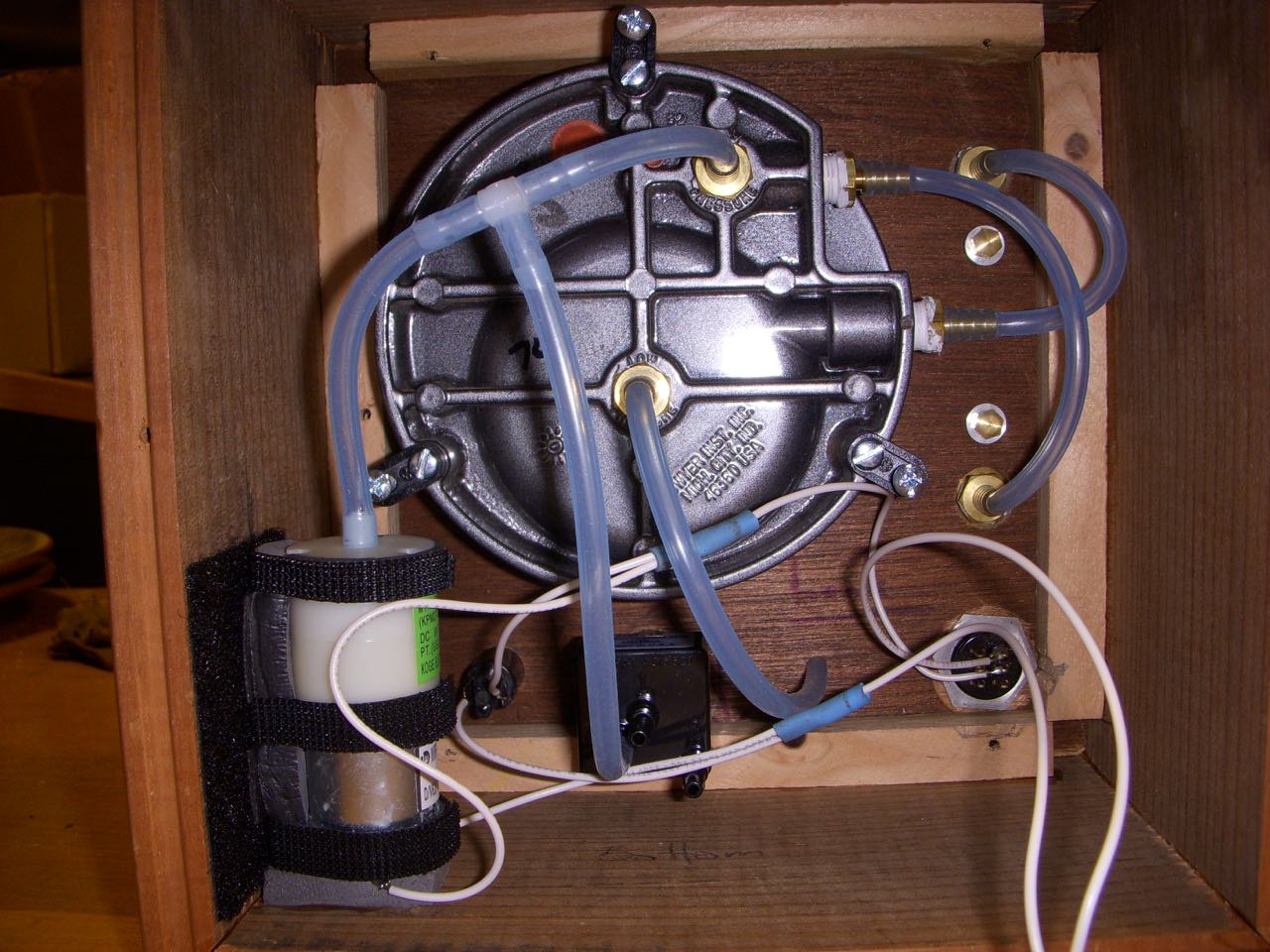

Plumbing installed.

Fairly simple really.

Meet the Magnehelic.